A catastrophic event in the mining industry typically involves a sudden and significant loss of life, substantial damage to property, and severe environmental consequences. Such incidents often stem from a combination of factors, including inadequate safety regulations, geological instability, human error, and equipment failure. A specific instance serves as a potent reminder of the inherent risks associated with resource extraction and the critical need for stringent safety protocols.

Studying such events provides invaluable insights into improving safety practices, preventing future tragedies, and understanding the complex interplay of human, technological, and environmental factors within the mining industry. Analysis of these incidents often leads to legislative changes, advancements in mining technology, and enhanced emergency response protocols. These advancements contribute significantly to worker safety, environmental protection, and the overall sustainability of the mining sector. Furthermore, understanding the historical context surrounding these events illuminates the societal impact of industrial disasters and the evolution of labor practices and regulations.

This article will delve deeper into the specific contributing factors, the immediate and long-term aftermath, and the lessons learned from a particular mining tragedy. It will also explore the broader implications for the mining industry and the ongoing efforts to improve safety and sustainability in resource extraction.

Safety Recommendations for Mining Operations

Preventing catastrophic incidents within the mining industry requires a multifaceted approach encompassing stringent regulations, robust safety protocols, and a commitment to continuous improvement. The following recommendations draw upon lessons learned from past tragedies to provide actionable guidance for enhancing safety and minimizing risks.

Tip 1: Comprehensive Risk Assessments: Conduct thorough and regular risk assessments of all mining operations, considering geological conditions, equipment integrity, and human factors. These assessments should be dynamic, adapting to changing circumstances and incorporating insights from near misses and minor incidents.

Tip 2: Stringent Safety Protocols: Implement and rigorously enforce comprehensive safety protocols covering all aspects of mining operations, from equipment maintenance and worker training to emergency response procedures. These protocols should be clearly documented, regularly reviewed, and updated to reflect best practices and industry standards.

Tip 3: Robust Communication Systems: Establish reliable communication systems throughout the mine, ensuring clear and timely communication between surface operations, underground personnel, and emergency responders. Redundancy in communication methods is crucial in the event of primary system failures.

Tip 4: Advanced Monitoring and Detection: Utilize advanced monitoring and detection technologies to identify potential hazards and mitigate risks. This includes real-time monitoring of gas levels, ground stability, and equipment performance. Early warning systems can provide critical time for evacuation and preventative measures.

Tip 5: Continuous Training and Education: Provide ongoing training and education for all mining personnel, emphasizing safety procedures, hazard recognition, and emergency response protocols. Regular drills and simulations are essential for reinforcing training and ensuring preparedness.

Tip 6: Independent Oversight and Audits: Establish independent oversight and regular safety audits to ensure compliance with regulations and best practices. External reviews provide an objective assessment of safety performance and identify areas for improvement.

Tip 7: Emergency Response Planning: Develop and regularly practice comprehensive emergency response plans, addressing potential scenarios such as fires, explosions, and ground collapses. These plans should include clear evacuation procedures, designated rescue teams, and readily available emergency equipment.

Adherence to these recommendations contributes significantly to a safer working environment, reduces the likelihood of catastrophic events, and promotes a culture of safety within the mining industry. Continuous learning and adaptation are crucial for maintaining high safety standards and protecting the lives of those who work in this demanding field.

In conclusion, the insights gained from past mining tragedies underscore the importance of proactive safety measures and a commitment to continuous improvement within the industry.

1. Cause

The catastrophic nature of the Smith Mining Disaster stems directly from a powerful methane explosion. Understanding the role of methane in coal mining, along with the specific circumstances that led to the ignition and rapid expansion of the gas, is crucial for comprehending the magnitude of this tragedy.

- Methane Occurrence in Coal Seams

Methane, a naturally occurring gas, is often trapped within coal seams. Mining operations, by their nature, disturb these seams and release the trapped methane. Without adequate ventilation and monitoring, methane concentrations can reach explosive levels.

- Ignition Sources in Underground Mines

Potential ignition sources within a coal mine are numerous, ranging from electrical sparks and malfunctioning equipment to open flames and blasting activities. In the case of the Smith Mine, the exact ignition source remains undetermined, highlighting the challenges in post-disaster investigations and the complex interplay of various risk factors.

- Rapid Expansion of Methane Explosions

The power of a methane explosion lies in its rapid expansion of hot gases, generating a devastating pressure wave that can propagate throughout the mine. This pressure wave causes structural damage, collapses tunnels, and displaces vast quantities of coal dust, potentially leading to secondary explosions and further exacerbating the disaster.

- Ventilation and Monitoring Systems

Effective ventilation systems are critical for diluting methane concentrations and preventing the buildup of explosive mixtures. Continuous monitoring of methane levels, coupled with robust safety protocols that dictate work stoppages when critical thresholds are reached, is essential for mitigating the risks associated with methane explosions.

The Smith Mining Disaster serves as a stark reminder of the ever-present danger of methane explosions in underground coal mining. The combination of methane’s natural occurrence in coal seams, the presence of potential ignition sources, and the devastating power of methane explosions underscores the need for stringent safety regulations, rigorous monitoring, and robust ventilation systems to protect the lives of miners and prevent future tragedies.

2. Date

March 9, 1924, marks the occurrence of a significant mining tragedythe Smith Mine disaster. This date signifies not merely a point in time but a pivotal moment that underscores the inherent dangers of the mining industry and the critical need for robust safety measures. Pinpointing the exact date allows for precise historical analysis, enabling researchers and safety advocates to understand the context surrounding the event, including prevailing mining practices, regulatory frameworks, and technological limitations of the era.

Examining the events leading up to and immediately following March 9, 1924, provides valuable insights into the chain of events that culminated in the disaster. This detailed chronological analysis is crucial for identifying systemic failures, pinpointing contributing factors, and developing preventative measures for future mining operations. Moreover, understanding the historical context of March 9, 1924, helps to appreciate the subsequent advancements in mining safety regulations, technology, and emergency response protocols that have emerged as a direct result of this and similar tragedies.

The significance of March 9, 1924, extends beyond its historical context. This date serves as a solemn reminder of the human cost of industrial accidents and the ongoing need for vigilance and continuous improvement in safety practices within the mining sector. Remembering and learning from this tragedy remains crucial for fostering a culture of safety and preventing future loss of life.

3. Location

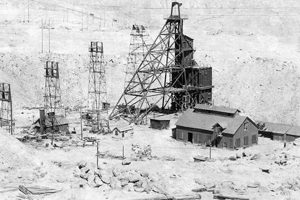

Smith Mine No. 3, the specific location of the 1924 disaster, plays a crucial role in understanding the event. The mine’s physical characteristics, including its geological composition, ventilation system, and layout, likely contributed to the disaster’s scale and severity. Analyzing these site-specific factors is essential for drawing meaningful conclusions about the causal chain of events. For instance, the mine’s geology might have influenced methane accumulation, while the ventilation system’s design could have impacted the gas’s distribution and subsequent ignition. Understanding the layout helps visualize the miners’ escape routes and the challenges they faced during the emergency.

The location itself, beyond its physical attributes, also holds significance. Smith Mine No. 3 operated within a specific regulatory environment and employed workers with varying levels of experience and training. Examining these socio-economic factors alongside the physical environment provides a richer understanding of the disaster’s multifaceted nature. Investigating the then-current mining regulations, the operator’s safety practices, and the workforce demographics provides valuable context. Such analysis might reveal whether regulatory gaps or inadequate training contributed to the tragic outcome. Comparing Smith Mine No. 3 to other mines operating under similar conditions could also illuminate best practices and areas for improvement.

Connecting the specific location, Smith Mine No. 3, with the broader disaster provides crucial lessons for improving mining safety. By studying the interplay of location-specific factors and wider industry practices, preventive strategies can be developed and implemented. This understanding facilitates the development of site-specific safety protocols and broader regulatory reforms. Ultimately, focusing on the “where” of the disaster, in conjunction with the “why” and “how,” offers critical insights into preventing future tragedies in the mining industry.

4. Fatalities

The Smith Mining Disaster’s devastating impact is most profoundly measured by the loss of 171 miners. This human cost underscores the inherent dangers of the mining industry and serves as a stark reminder of the importance of safety regulations and preventative measures. Examining the circumstances surrounding these fatalities provides crucial insights into the disaster’s immediate consequences and its long-term impact on families, communities, and the industry itself.

- Immediate Aftermath and Rescue Efforts

The sheer number of fatalities significantly complicated rescue and recovery efforts. The scale of the disaster overwhelmed available resources, delaying access to trapped miners and hindering the identification and retrieval of bodies. The immediate aftermath highlighted the need for improved emergency response protocols and greater capacity for handling mass casualty events in the mining industry.

- Impact on Families and Communities

The loss of 171 miners had a profound and lasting impact on families and surrounding communities. The economic hardship faced by widows and orphans, coupled with the emotional trauma of sudden loss, rippled through the social fabric of these communities. The disaster underscored the need for comprehensive support systems for mining families, including financial assistance, grief counseling, and job retraining programs.

- Investigations and Regulatory Changes

The magnitude of the loss of life prompted thorough investigations into the causes of the Smith Mining Disaster. These investigations often lead to stricter safety regulations, improved inspection protocols, and the development of new technologies aimed at preventing similar tragedies. The 171 fatalities served as a catalyst for significant reforms within the mining industry, driving a greater focus on worker safety and risk mitigation.

- Memorialization and Remembrance

The 171 miners who perished in the Smith Mining Disaster are often memorialized through monuments, museums, and annual remembrance ceremonies. These acts of commemoration serve to honor the victims, preserve their memory, and remind future generations of the importance of prioritizing safety in the mining industry. These memorials also stand as a testament to the human cost of industrial accidents and the ongoing need for vigilance in preventing future tragedies.

The 171 fatalities of the Smith Mining Disaster represent more than just a statistic; they represent individual lives lost, families shattered, and communities forever changed. Understanding the human cost of this tragedy is essential for shaping future safety regulations, promoting a culture of safety within the mining industry, and ensuring that such a devastating loss of life never happens again.

5. Rescue Efforts

The Smith Mining Disaster’s devastating aftermath presented significant challenges for rescue efforts, primarily due to the extensive debris generated by the methane explosion. The force of the blast caused widespread structural damage, collapsing tunnels, and scattering vast quantities of rock and coal throughout the mine. This chaotic environment created numerous obstacles for rescuers attempting to locate and extract survivors. The debris hindered access to affected areas, making it difficult to assess the full extent of the damage and identify potential escape routes. Navigating through the unstable rubble posed significant risks to rescuers themselves, further complicating and delaying rescue operations. The presence of debris also created additional hazards, such as the potential for further collapses and the release of trapped methane, increasing the risk of secondary explosions.

The hampered rescue efforts underscore the critical need for effective emergency preparedness and response protocols in mining disasters. Pre-disaster planning, including detailed mine maps, designated escape routes, and readily available emergency equipment, can significantly improve the chances of successful rescues. Specialized training for rescue teams in navigating debris-filled environments, utilizing advanced search and rescue technologies, and managing secondary hazards is essential for optimizing rescue operations in the aftermath of a mining disaster. Furthermore, effective communication systems between surface operations, underground personnel, and rescue teams are crucial for coordinating efforts and maximizing efficiency in challenging circumstances. The Smith Mining Disaster provides a stark example of how debris can impede rescue efforts, emphasizing the necessity of preparedness and specialized training to mitigate the impact of such obstacles in future mining emergencies.

The challenges faced by rescue teams at the Smith Mining Disaster highlight the crucial link between the physical consequences of a mining disaster and the effectiveness of subsequent rescue operations. The extensive debris not only directly hindered access to potential survivors but also created additional hazards, amplifying the risks faced by both trapped miners and rescuers. This understanding underscores the importance of robust pre-disaster planning, specialized training, and advanced rescue technologies in minimizing loss of life and maximizing the effectiveness of emergency response in future mining tragedies.

6. Impact

The Smith Mining Disaster served as a tragic catalyst for significant advancements in mining safety regulations. The scale of the disaster exposed critical deficiencies in existing safety practices and spurred widespread demands for reform. The incident’s aftermath led to a comprehensive reassessment of mining regulations, resulting in more stringent rules and enhanced enforcement mechanisms. This shift towards stricter regulations aimed to address the root causes of the disaster and prevent similar tragedies in the future. The connection between the disaster and subsequent regulatory changes exemplifies the crucial role of tragic events in driving improvements in industrial safety.

Several key regulatory changes emerged in response to the Smith Mining Disaster. These included enhanced ventilation standards to mitigate methane accumulation, stricter protocols for handling explosives and electrical equipment, and improved requirements for mine inspections and emergency response plans. For example, mandatory methane monitoring systems became more commonplace, alongside regulations mandating the use of flame-safety lamps. The implementation of these stricter regulations represented a significant step forward in prioritizing miner safety and holding mining companies accountable for maintaining safe working environments. The disaster’s legacy is evident in the lasting impact it had on shaping mining safety practices and influencing legislative reforms across the industry.

Understanding the connection between the Smith Mining Disaster and the subsequent stricter safety regulations is crucial for appreciating the ongoing evolution of safety practices in the mining industry. While the disaster itself represents a profound loss, the resulting regulatory changes demonstrate the capacity for tragedy to drive positive change. The implementation of stricter safety standards serves not only as a memorial to the lives lost but also as a vital component in building a safer and more sustainable future for the mining industry. The challenge remains to continuously learn from past tragedies, adapt to evolving technologies and mining practices, and maintain a steadfast commitment to prioritizing miner safety above all else.

7. Legacy

The establishment of a memorial park following the Smith Mining Disaster represents a tangible and enduring legacy of the tragedy. This physical space serves not only as a place of remembrance for the 171 miners who perished but also as a powerful symbol of the ongoing commitment to mining safety. The park’s existence directly results from the disaster, transforming a site of immense sorrow into a place of reflection and a reminder of the human cost of industrial accidents. Memorial parks, in the context of mining disasters, often evolve into focal points for community healing and remembrance, offering solace to grieving families and providing a space for collective mourning.

The memorial park’s significance extends beyond its commemorative function. It stands as a constant reminder of the importance of prioritizing safety in the mining industry. By preserving the memory of the Smith Mining Disaster, the park encourages ongoing dialogue about safety regulations, best practices, and the need for continuous improvement in risk mitigation. The park’s educational potential can be further enhanced through interpretive displays, historical information, and interactive exhibits that detail the events of the disaster, its causes, and the subsequent changes in mining safety practices. Such initiatives transform the park into a living testament to the ongoing pursuit of safer working conditions for miners. Furthermore, the memorial park can serve as a venue for annual commemorations, gatherings of families affected by the disaster, and community events focused on promoting mining safety awareness.

The creation of a memorial park following the Smith Mining Disaster demonstrates the complex interplay between tragedy and remembrance. The park’s existence acknowledges the profound loss while simultaneously offering a space for healing, reflection, and education. Its enduring presence ensures that the lessons learned from the disaster are not forgotten, contributing to a lasting legacy of improved safety practices and a renewed commitment to protecting the lives of those who work in the mining industry. The park’s continued relevance underscores the ongoing need for vigilance and the importance of remembering past tragedies to prevent future occurrences.

Frequently Asked Questions

This section addresses common inquiries regarding the Smith Mining Disaster, providing concise and informative responses based on available historical data and research.

Question 1: What was the primary cause of the Smith Mining Disaster?

A methane gas explosion ignited by an unknown source triggered the catastrophic event.

Question 2: How many lives were lost in the disaster?

The Smith Mining Disaster claimed the lives of 171 miners.

Question 3: When and where did the disaster occur?

The disaster struck Smith Mine No. 3 on March 9, 1924.

Question 4: What were the primary challenges faced by rescue teams?

Extensive debris and unstable conditions within the mine significantly hampered rescue efforts.

Question 5: What was the long-term impact of the disaster on the mining industry?

The disaster led to stricter safety regulations, improved inspection protocols, and a greater emphasis on miner safety.

Question 6: How is the disaster remembered today?

A memorial park now stands at the site, serving as a place of remembrance and a reminder of the importance of mining safety.

Understanding the Smith Mining Disaster through these frequently asked questions offers valuable insights into the complexities of mining safety and the importance of continuous improvement in preventing future tragedies. Each question and answer provides a glimpse into the events of that fateful day and its lasting impact on the mining industry and the affected community.

Further exploration of specific aspects of the Smith Mining Disaster can be found in the following sections.

Conclusion

The Smith Mining Disaster serves as a sobering reminder of the inherent risks associated with resource extraction. This tragic event, resulting in substantial loss of life, underscores the critical importance of stringent safety regulations, robust emergency response protocols, and a sustained commitment to continuous improvement within the mining industry. Analysis of the disaster’s contributing factors, including methane accumulation, ignition sources, and the challenges faced by rescue teams, provides invaluable lessons for preventing future tragedies. The subsequent implementation of stricter safety standards and the establishment of a memorial park demonstrate the capacity for such events to drive positive change and foster a culture of safety.

Continued vigilance and proactive measures are essential to ensuring the well-being of those who work in the demanding and often hazardous environment of the mining industry. Learning from past tragedies, such as the Smith Mining Disaster, remains crucial for mitigating risks, enhancing safety protocols, and striving towards a future where such devastating losses are prevented. The legacy of the Smith Mining Disaster should serve as a constant reminder of the industry’s responsibility to prioritize safety and protect the lives of its workforce.