This specific incident, often referred to with a descriptive term involving a warm beverage and a mishap, generally signifies an event where unforeseen circumstances lead to a significant negative outcome related to the preparation or consumption of hot chocolate. An example could be a large-scale recall of a product due to contamination, a significant equipment malfunction at a processing plant, or a widely publicized incident of foodborne illness linked to the beverage. The specific parameters defining such an occurrence can vary widely, depending on the context and scale of the event.

Analyzing such events provides valuable insights into food safety protocols, supply chain vulnerabilities, and consumer behavior. Studying the contributing factors, consequences, and subsequent corrective actions offers opportunities for improving manufacturing processes, regulatory oversight, and public awareness. Historical context can illuminate recurring patterns and inform preventive measures, contributing to a more robust and resilient food system. Examining specific occurrences can further elucidate best practices in crisis management, communication strategies, and public health interventions.

The following sections will delve deeper into specific instances, examine their underlying causes, and analyze their broader implications for the food and beverage industry. Additionally, the discussion will explore the role of regulatory bodies, the evolution of safety standards, and the ongoing efforts to mitigate future risks associated with food and beverage production and consumption.

Preventive Measures Against Beverage-Related Incidents

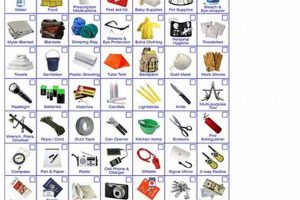

Learning from past incidents, whether large-scale or localized, offers valuable lessons in risk mitigation. The following recommendations aim to minimize the likelihood of similar occurrences, focusing on proactive steps applicable to various scenarios involving beverages like hot chocolate.

Tip 1: Rigorous Supplier Vetting: Thoroughly assess suppliers for adherence to stringent quality control measures and safety certifications. Verification of sourcing practices and ingredient quality is crucial.

Tip 2: Meticulous Ingredient Inspection: Implement rigorous incoming ingredient inspections. This includes visual checks, appropriate testing for contaminants, and documentation of findings.

Tip 3: Controlled Preparation Processes: Establish and adhere to standardized preparation procedures, including precise temperature controls and hygiene protocols. Regular equipment maintenance and calibration are essential.

Tip 4: Proper Storage and Handling: Maintain appropriate storage temperatures for both ingredients and finished products. Implement FIFO (First In, First Out) inventory management to minimize spoilage and ensure product freshness.

Tip 5: Employee Training and Hygiene: Comprehensive training on food safety practices, hygiene standards, and proper handling procedures is essential for all personnel involved in the preparation and serving processes.

Tip 6: Prompt Contamination Response: Develop a clear protocol for responding to potential contamination incidents. This should include procedures for product recall, public notification, and cooperation with relevant authorities.

Tip 7: Continuous Monitoring and Improvement: Regularly review and update safety protocols based on industry best practices, regulatory updates, and lessons learned from past incidents. Implement a system for tracking and analyzing near misses.

By implementing these precautions, organizations can significantly reduce the risk of incidents and maintain consumer confidence in the safety and quality of their products.

This proactive approach to risk management not only safeguards public health but also protects brand reputation and fosters a culture of continuous improvement within the food and beverage industry. The following section will offer concluding remarks and further resources for ongoing learning and development in this critical area.

1. Contamination

Contamination represents a critical factor in incidents related to food and beverages, exemplified by the hypothetical “hot chocolate disaster.” Whether stemming from biological agents (bacteria, viruses, parasites), chemical substances (pesticides, heavy metals, cleaning agents), or physical objects (glass shards, metal fragments, plastic pieces), contamination can have profound consequences. The presence of contaminants can render a product unsafe for consumption, leading to potential health issues ranging from mild discomfort to severe illness or even fatalities. The source of contamination can vary, originating from raw materials, processing equipment, packaging materials, or human error during handling and preparation.

Several real-world examples highlight the significant impact of contamination. The 2008 melamine contamination of infant formula in China, though not directly involving hot chocolate, underscores the devastating consequences of adulterated food products. Similarly, numerous recalls of food items due to bacterial contamination, such as Salmonella or E. coli, demonstrate the ongoing challenges in maintaining food safety standards. While a specific “hot chocolate disaster” might be a hypothetical construct, the underlying principles of contamination and its potential repercussions remain critically relevant to the food and beverage industry.

Understanding the various pathways to contamination and the potential severity of its consequences is crucial for developing effective preventive measures. This includes robust quality control systems throughout the supply chain, stringent hygiene protocols during processing and handling, and meticulous testing procedures to detect contaminants before products reach consumers. By prioritizing food safety and implementing rigorous preventive strategies, the industry can minimize the risk of contamination-related incidents and safeguard public health.

2. Equipment Malfunction

Equipment malfunction represents a significant contributing factor to potential incidents within the food and beverage industry, including scenarios analogous to “the hot chocolate disaster.” Failures in processing, packaging, or storage equipment can introduce contaminants, compromise product quality, and create safety hazards. Understanding the various types of malfunctions and their potential consequences is crucial for developing effective preventative maintenance and emergency response protocols.

- Heating System Failures

Malfunctions in heating systems used for pasteurization or hot beverage preparation can lead to inadequate heat treatment, potentially allowing harmful microorganisms to survive. Inconsistent heating can also affect product quality, resulting in undesirable texture or flavor changes. A real-world example includes instances where insufficient heating during canning processes has led to botulism outbreaks. In the context of a “hot chocolate disaster,” a faulty heating system could result in a product susceptible to bacterial growth, posing a significant health risk to consumers.

- Packaging Equipment Issues

Problems with packaging equipment, such as sealers or fillers, can compromise product integrity and introduce contaminants. Leaking seals can expose the product to external contaminants, while malfunctioning fillers might introduce foreign objects. Recalls of packaged foods due to compromised seals or foreign object contamination are not uncommon. In a “hot chocolate disaster” scenario, faulty packaging equipment could result in contaminated or spoiled product reaching consumers.

- Grinding/Mixing Machinery Problems

Malfunctions in grinding or mixing machinery, particularly in the production of powdered beverages like hot chocolate mix, can result in uneven particle size distribution or inadequate mixing of ingredients. This can affect product consistency and potentially introduce physical contaminants from worn or broken parts. Instances of metal fragments found in ground spices illustrate the risks associated with malfunctioning grinding equipment. In a “hot chocolate disaster,” similar issues could lead to consumer complaints or even injuries.

- Temperature Control System Failures

Failures in temperature control systems, especially during storage, can lead to spoilage or the growth of pathogens. Fluctuations in temperature can create environments conducive to bacterial proliferation. Numerous instances of food spoilage due to improper refrigeration highlight the importance of reliable temperature control. In the context of a “hot chocolate disaster,” temperature control failures during storage could lead to product degradation or the development of harmful toxins.

These examples illustrate how equipment malfunctions can contribute to a “hot chocolate disaster” or similar incidents. A comprehensive preventative maintenance program, coupled with robust quality control measures and prompt response protocols, is essential for mitigating these risks and ensuring product safety. By addressing potential equipment-related vulnerabilities, the food and beverage industry can enhance consumer safety and protect brand reputation.

3. Supply Chain Disruption

Supply chain disruptions represent a significant vulnerability within the food and beverage industry, capable of contributing to scenarios analogous to “the hot chocolate disaster.” These disruptions, stemming from various factors such as natural disasters, geopolitical instability, transportation bottlenecks, or supplier failures, can compromise the timely delivery of ingredients and finished products. Such disruptions can lead to shortages, increased costs, and potential quality issues, impacting consumer access to products and potentially creating opportunities for contamination or adulteration. Examining the potential causes and consequences of supply chain disruptions is crucial for understanding their role in food safety incidents.

Consider the impact of a sudden shortage of cocoa beans, a key ingredient in hot chocolate. This shortage could lead manufacturers to seek alternative suppliers, potentially with less stringent quality control measures. The resulting product might be of inferior quality or even contaminated, leading to a “hot chocolate disaster” scenario. Similarly, transportation delays could cause ingredients to spoil or become contaminated during transit, posing a risk to consumers. Real-world examples, such as the disruption of global supply chains during the COVID-19 pandemic, underscore the vulnerability of intricate networks and the potential for cascading effects throughout the food and beverage sector. The 2022 infant formula shortage in the United States, while not directly related to hot chocolate, provides another pertinent example of how supply chain disruptions can impact access to essential food products and create vulnerability to contamination risks. These events highlight the importance of robust supply chain management, diversification of suppliers, and contingency planning to mitigate the impact of unforeseen disruptions.

Understanding the interconnectedness of supply chain vulnerabilities and the potential for food safety incidents is critical for developing effective mitigation strategies. Diversifying sourcing, implementing robust tracking and traceability systems, and fostering strong relationships with suppliers can enhance supply chain resilience. Furthermore, proactive risk assessments and contingency planning can equip organizations to respond effectively to disruptions, minimizing the potential for a “hot chocolate disaster” or other similar incidents. By recognizing and addressing supply chain vulnerabilities, the food and beverage industry can enhance its ability to navigate unforeseen challenges and maintain the safety and integrity of its products.

4. Consumer Illness

Consumer illness stands as a central consequence in any scenario resembling “the hot chocolate disaster.” Contaminated or improperly handled hot chocolate can lead to a range of health issues, depending on the nature of the contaminant or error. Bacterial contamination can cause foodborne illnesses like salmonellosis or E. coli infection, characterized by symptoms such as diarrhea, vomiting, and fever. Chemical contaminants can lead to more severe health problems, including neurological damage or long-term health complications. Physical contaminants, such as foreign objects in the product, can cause injuries like choking or lacerations. The severity of consumer illness directly impacts public perception and the magnitude of any subsequent crisis.

The 2008 melamine contamination of infant formula in China, while not involving hot chocolate, serves as a stark reminder of the potential severity of consumer illness resulting from contaminated food products. Thousands of infants suffered kidney damage, and several deaths were reported. While a hypothetical “hot chocolate disaster” might not reach such a scale, the potential for widespread illness underscores the critical importance of food safety protocols. Even less severe instances of foodborne illness can lead to product recalls, brand damage, and legal repercussions. Understanding the potential health consequences associated with contaminated or mishandled food products is crucial for developing effective prevention and mitigation strategies.

Addressing the risk of consumer illness requires a multi-pronged approach, encompassing stringent quality control measures throughout the supply chain, rigorous hygiene practices during production and handling, and clear procedures for responding to potential contamination incidents. Rapid and effective communication with consumers in the event of a contamination incident is also crucial for minimizing the impact on public health. The potential for consumer illness highlights the critical link between food safety practices and public health outcomes. By prioritizing food safety at every stage, from ingredient sourcing to consumer consumption, the food and beverage industry can protect consumers and maintain public trust.

5. Brand Damage

Brand damage represents a significant consequence of food safety incidents, particularly those with widespread public awareness, such as a hypothetical “hot chocolate disaster.” A brand’s reputation, built over time through investment and consistent quality, can be severely compromised by a single incident that erodes consumer trust. The resulting loss of sales, negative media coverage, and legal repercussions can have long-lasting financial and reputational implications. Understanding the multifaceted nature of brand damage is crucial for developing effective mitigation strategies.

- Loss of Consumer Trust

Consumer trust, a cornerstone of brand loyalty, can be irrevocably damaged by a food safety incident. Consumers who experience illness or perceive a risk associated with a particular brand are likely to switch to competitors. The 2008 melamine contamination of infant formula in China led to a widespread boycott of the implicated brands, demonstrating the profound impact of lost consumer trust. In a “hot chocolate disaster” scenario, similar erosion of trust could lead to significant and sustained declines in sales.

- Negative Media Coverage

Food safety incidents often attract significant media attention, amplifying the negative impact on brand perception. News reports, social media discussions, and online reviews can quickly disseminate information about a product recall or consumer illness, potentially reaching a global audience. The 2015 Chipotle E. coli outbreaks resulted in extensive negative media coverage, significantly impacting the company’s brand image and stock value. A “hot chocolate disaster” could similarly generate negative publicity, exacerbating the brand damage.

- Legal and Regulatory Scrutiny

Food safety incidents often trigger investigations by regulatory agencies and potential legal action from affected consumers. Product recalls, fines, and lawsuits can impose substantial financial burdens on a company. The peanut butter contamination cases involving Salmonella outbreaks in the late 2000s led to criminal charges and significant financial penalties for the responsible company. A “hot chocolate disaster” could similarly result in legal and regulatory challenges, further compounding the brand damage.

- Long-Term Reputational Impact

The reputational damage from a food safety incident can persist long after the immediate crisis has subsided. Consumers may harbor negative associations with the implicated brand for years, impacting future purchasing decisions. The long-term reputational damage from the Tylenol tampering incidents in the 1980s, while not directly related to food, illustrates the enduring impact of safety breaches on consumer perception. A “hot chocolate disaster,” even if effectively managed in the short term, could have lasting repercussions on brand perception and consumer loyalty.

These facets of brand damage underscore the interconnectedness of product safety, public perception, and business outcomes. A “hot chocolate disaster,” or any similar food safety incident, can have a devastating impact on a brand’s reputation and long-term viability. Proactive measures to ensure product safety, coupled with effective crisis communication and remediation strategies, are crucial for mitigating the risk of brand damage and maintaining consumer trust.

6. Regulatory Scrutiny

Regulatory scrutiny plays a crucial role in the aftermath of food safety incidents, particularly those that reach the scale of a hypothetical “hot chocolate disaster.” Government agencies, tasked with protecting public health and ensuring food safety standards, investigate the causes of such incidents, implement corrective actions, and impose penalties on responsible parties. This scrutiny aims to prevent future occurrences, enhance industry practices, and maintain consumer confidence in the food supply. Understanding the scope and impact of regulatory scrutiny is essential for mitigating the consequences of a “hot chocolate disaster.”

A significant incident involving hot chocolate, such as widespread contamination or consumer illness, would inevitably trigger investigations by regulatory bodies like the Food and Drug Administration (FDA) in the United States or the European Food Safety Authority (EFSA) in Europe. These investigations might involve product testing, facility inspections, and reviews of manufacturing processes. Depending on the severity and scope of the incident, regulatory actions could range from product recalls and warning letters to fines, plant closures, and even criminal charges. The 2011 peanut butter Salmonella outbreak, which resulted in criminal convictions and significant fines for the responsible company, illustrates the potential consequences of regulatory scrutiny. While not directly related to hot chocolate, this case demonstrates the seriousness with which regulatory bodies address food safety violations. Similarly, the numerous recalls of food products due to bacterial contamination or undeclared allergens highlight the ongoing role of regulatory oversight in maintaining food safety standards.

The potential for regulatory scrutiny underscores the importance of proactive measures to ensure food safety throughout the supply chain. Robust quality control systems, adherence to good manufacturing practices (GMPs), and transparent traceability systems can help companies avoid regulatory violations and mitigate the consequences of a “hot chocolate disaster.” Furthermore, effective communication and cooperation with regulatory agencies during an incident can help facilitate a swift and appropriate response, minimizing the impact on public health and brand reputation. Understanding the role and implications of regulatory scrutiny is critical for navigating the complex landscape of food safety regulations and maintaining consumer trust.

7. Public Perception

Public perception plays a pivotal role in the unfolding and aftermath of a food safety incident like a hypothetical “hot chocolate disaster.” Consumer confidence, shaped by media coverage, social media discussions, and personal experiences, significantly influences the extent and duration of the impact. Negative public perception can lead to boycotts, decreased sales, and long-term reputational damage, even if the actual health risks are limited. Conversely, proactive and transparent communication can mitigate negative perceptions and help restore trust.

Consider a scenario where a batch of hot chocolate mix is recalled due to potential contamination. Even if the contamination is minor and no illnesses are reported, negative media coverage and social media amplification can create a perception of widespread risk. This perception can trigger a decline in sales, not only for the specific product but also for other products from the same brand. The 2011 Fukushima Daiichi nuclear disaster, while unrelated to food, provides a relevant example of how public perception can outweigh actual risk. The fear of radiation contamination led to widespread avoidance of Japanese products, even those with negligible risk. Similarly, a “hot chocolate disaster,” even if contained, could trigger a disproportionate public reaction due to amplified perceptions of risk. Conversely, consider the Tylenol tampering incidents of the 1980s. Johnson & Johnson’s swift and transparent response, including a nationwide recall and introduction of tamper-resistant packaging, effectively addressed public concerns and helped rebuild trust, despite the criminal nature of the incident.

Managing public perception during a food safety crisis requires proactive and transparent communication. Providing timely and accurate information about the incident, the scope of the problem, and the steps taken to address it can help mitigate negative perceptions. Openly acknowledging the issue and demonstrating a commitment to consumer safety can help rebuild trust. Effective communication strategies, coupled with tangible actions to correct the problem and prevent future occurrences, are essential for navigating the complexities of public perception and safeguarding brand reputation in the wake of a food safety incident.

Frequently Asked Questions

This section addresses common concerns and misconceptions regarding potential incidents related to hot chocolate or similar beverage products, often referred to metaphorically as a “disaster.”

Question 1: How likely is a large-scale incident involving contaminated hot chocolate?

While large-scale incidents are rare due to stringent safety regulations and quality control measures, the possibility cannot be entirely dismissed. Multiple factors, including ingredient sourcing, manufacturing processes, and handling procedures, contribute to the overall risk.

Question 2: What are the typical signs of hot chocolate contamination?

Signs of contamination can vary depending on the contaminant. Unusual odors, off-flavors, discoloration, or the presence of foreign objects are potential indicators. If a product appears suspect, consumption should be avoided, and the manufacturer or retailer should be contacted.

Question 3: What should consumers do if they suspect they have consumed contaminated hot chocolate?

If symptoms of illness occur after consuming hot chocolate, medical advice should be sought immediately. Preserving the remaining product and packaging can assist in identifying the source of contamination. Reporting the incident to the relevant authorities is also recommended.

Question 4: How can consumers minimize the risk of purchasing or consuming contaminated hot chocolate?

Purchasing products from reputable manufacturers and retailers known for their commitment to food safety is advisable. Checking product packaging for damage or tampering is also recommended. Proper storage and preparation practices at home further minimize risks.

Question 5: What role do regulatory agencies play in preventing hot chocolate-related incidents?

Regulatory agencies establish and enforce food safety standards, conduct inspections, and investigate reported incidents. These agencies play a crucial role in ensuring product safety and holding manufacturers accountable for maintaining appropriate quality control measures.

Question 6: What measures do hot chocolate manufacturers take to ensure product safety?

Reputable manufacturers implement stringent quality control procedures throughout the production process, from ingredient sourcing to packaging. These procedures typically include testing for contaminants, adherence to good manufacturing practices (GMPs), and robust traceability systems.

Prioritizing food safety and understanding potential risks are crucial for both consumers and manufacturers. Vigilance, adherence to best practices, and effective communication contribute to a safer food supply chain.

The following section will offer concluding remarks and further resources for ongoing learning and development in this critical area.

Conclusion

This exploration of a hypothetical “hot chocolate disaster” has illuminated critical vulnerabilities within the food and beverage industry. From contamination and equipment malfunctions to supply chain disruptions and the subsequent repercussions of consumer illness, brand damage, regulatory scrutiny, and shifts in public perception, the potential consequences of a large-scale incident are substantial. The analysis underscores the interconnectedness of these elements and the importance of proactive measures to mitigate risks.

Safeguarding the food supply requires a concerted effort from all stakeholders. Manufacturers must prioritize stringent quality control, robust safety protocols, and transparent communication. Consumers benefit from informed purchasing decisions and adherence to safe handling practices. Regulatory agencies play a vital role in enforcing standards and holding manufacturers accountable. Continuous vigilance, proactive risk assessment, and a commitment to continuous improvement are essential for preventing a “hot chocolate disaster” and ensuring the safety and integrity of the food and beverage industry.