The horrific event that transpired on March 25, 1911, in a New York City garment factory claimed the lives of 146 workers, mostly young immigrant women. Trapped by locked doors and inadequate fire escapes, many perished in the flames or leaped to their deaths from the burning building’s upper floors. The factory, located in the Asch Building, epitomized the unsafe working conditions prevalent in many early 20th-century industrial settings.

This tragedy served as a pivotal moment in American labor history. Public outcry over the immense loss of life and the demonstrably unsafe conditions that contributed to it spurred significant reforms in workplace safety regulations. The disaster galvanized the labor movement, leading to strengthened unions and increased advocacy for worker protections, including fire safety codes, factory inspections, and improved working conditions. Its legacy continues to resonate in contemporary discussions about worker rights and safety standards.

Further exploration of this event will cover topics such as the victims’ stories, the subsequent investigations and legal proceedings, the long-term impact on labor laws, and the enduring significance of this tragedy in shaping modern safety standards.

Improving Workplace Safety

The 1911 tragedy provides invaluable lessons for contemporary workplace safety. Understanding the factors that contributed to the loss of life can inform preventative measures and promote a culture of safety.

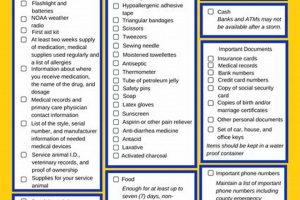

Tip 1: Ensure Clear and Accessible Escape Routes: Locked or obstructed exits significantly contributed to the high death toll. Multiple, well-marked exits should be easily accessible to all occupants, and evacuation procedures practiced regularly.

Tip 2: Implement and Maintain Fire Safety Equipment: Functional fire alarms, extinguishers, and sprinkler systems are essential. Regular inspections and maintenance are crucial to ensure their effectiveness in an emergency.

Tip 3: Enforce Strict Fire Safety Regulations: Regular inspections by fire marshals and adherence to fire codes are critical. Negligence in maintaining safety standards should be addressed swiftly and decisively.

Tip 4: Prioritize Employee Training and Education: All employees should receive comprehensive training on fire safety procedures, including evacuation plans and the proper use of fire safety equipment.

Tip 5: Empower Workers to Report Unsafe Conditions: Creating a culture where employees feel safe reporting hazards without fear of reprisal is crucial. These reports should be investigated promptly and corrective actions taken.

Tip 6: Regularly Evaluate and Update Safety Protocols: Workplace safety is not static. Regular reviews and updates to safety procedures are essential to adapt to changing conditions and incorporate best practices.

By understanding and applying these lessons, workplaces can significantly mitigate fire risks and create a safer environment for all. The goal is to prevent such a devastating event from ever happening again.

The legacy of this tragedy serves as a constant reminder of the importance of prioritizing workplace safety and advocating for continuous improvement in safety standards and regulations.

1. Unsafe Working Conditions

The Triangle Shirtwaist Factory disaster serves as a chilling example of the tragic consequences of unsafe working conditions. The factory environment posed numerous hazards that ultimately contributed to the devastating loss of life on that fateful day. Examining these conditions provides critical context for understanding the magnitude of the disaster and its lasting impact on labor regulations.

- Overcrowding and Blocked Exits:

The factory floor was severely overcrowded with sewing machines and work tables, hindering movement and escape. Exits were limited, and some doors were reportedly locked to prevent theft and unauthorized breaks, trapping workers inside during the fire. This egregious disregard for safety regulations directly contributed to the high death toll.

- Flammable Materials and Lack of Fire Suppression:

The presence of highly flammable materials like fabric scraps and oil-soaked machinery fueled the rapid spread of the fire. The lack of adequate fire suppression systems, such as sprinklers, exacerbated the situation. The combination of these factors created a perfect storm for disaster.

- Inadequate Fire Escapes:

The existing fire escapes were poorly designed and insufficient for the number of workers in the building. One fire escape collapsed under the weight of panicked employees, while others were blocked or difficult to access. This failure of essential safety infrastructure proved fatal for many.

- Lack of Safety Regulations and Enforcement:

The lax regulatory environment at the time contributed to the dangerous conditions within the factory. Inspections were infrequent and often inadequate, allowing hazardous practices to continue unchecked. This lack of oversight ultimately enabled the creation of a deathtrap.

These unsafe working conditions, combined with the rapid spread of the fire and the panicked response, created a horrific scenario from which escape was nearly impossible for many workers. The Triangle Shirtwaist Factory disaster stands as a grim reminder of the critical importance of workplace safety regulations and their rigorous enforcement. The tragedy spurred significant changes in labor laws, pushing for improved safety standards and worker protections that continue to shape workplace safety practices today.

2. Locked Factory Doors

Locked factory doors played a tragically significant role in the Triangle Shirtwaist Factory disaster. This practice, ostensibly implemented to prevent theft and unauthorized breaks, became a death sentence for many workers when fire erupted. Examining the implications of this seemingly mundane detail reveals a deeper understanding of the disaster’s severity and its impact on subsequent safety regulations.

- Obstructed Escape Routes:

The locked doors directly obstructed escape routes, trapping workers inside the burning building. With limited exits available, the locked doors created bottlenecks and prevented efficient evacuation, contributing significantly to the high casualty count. The desperate attempts to open the locked doors amidst the chaos and smoke further exacerbated the panic and hampered rescue efforts.

- Amplified Panic and Chaos:

The realization that escape routes were blocked intensified the panic among the trapped workers. The locked doors transformed a desperate situation into an utter nightmare, leading to further chaos and hindering organized evacuation attempts. This widespread panic likely contributed to the pile-up of bodies at the locked exits, as documented in the aftermath.

- Violation of Safety Standards (Where Applicable):

While formal fire codes were still developing at the time, the practice of locking factory doors demonstrably violated basic safety principles. This disregard for worker safety underscored the need for stronger regulations and more rigorous enforcement, which became a focal point of subsequent labor reforms.

- Symbol of Industrial Neglect:

The locked doors became a potent symbol of the prevailing industrial negligence of the era. The prioritization of preventing minor theft over ensuring worker safety highlighted the dehumanizing conditions faced by many factory employees and fueled public outrage in the disaster’s aftermath. This outrage contributed to significant momentum for change in worker protection laws.

The locked doors of the Triangle Shirtwaist Factory serve as a stark reminder of how seemingly small decisions can have devastating consequences in the context of a larger disaster. This tragic detail highlights the critical need for prioritizing life safety in all workplace environments and ensuring that safety regulations are not only implemented but also strictly enforced. The legacy of this disaster continues to inform modern fire safety codes and underscores the importance of accessible escape routes in any building.

3. Inadequate Fire Escapes

The inadequate fire escapes of the Asch Building, where the Triangle Shirtwaist Factory was located, played a crucial role in the tragic loss of life during the 1911 fire. These insufficient escape routes turned a dangerous situation into a catastrophe, trapping workers and contributing significantly to the high death toll. Examining the specific inadequacies of the fire escapes provides critical insight into the disaster’s severity and the subsequent push for improved building safety standards.

- Insufficient Capacity:

The fire escapes were simply not designed to accommodate the large number of workers occupying the factory. With hundreds of employees trying to escape simultaneously, the limited capacity of the fire escapes created dangerous bottlenecks and delays. This overcrowding likely contributed to the collapse of one fire escape under the weight of panicked workers, further hindering escape and resulting in additional fatalities.

- Poor Design and Construction:

The fire escapes themselves were poorly designed and constructed. Some were narrow and difficult to navigate, especially in the smoke and chaos of the fire. Others were constructed of flimsy materials that proved incapable of supporting the weight of numerous people, leading to structural failures during the evacuation attempt.

- Obstructed Access:

Access to the fire escapes was often obstructed by machinery, materials, and locked doors. This further hampered escape efforts and contributed to the sense of panic and desperation among the trapped workers. The difficulty in reaching the fire escapes turned what should have been a lifeline into another obstacle.

- Lack of Regular Inspection and Maintenance:

The lack of regular inspection and maintenance of the fire escapes likely contributed to their poor condition and ultimate failure. Had these safety features been properly maintained and inspected, some of the structural weaknesses and access issues might have been identified and addressed before the disaster occurred.

The inadequate fire escapes at the Triangle Shirtwaist Factory stand as a grim testament to the consequences of neglecting building safety. This critical factor, combined with other hazardous conditions within the factory, directly contributed to the immense loss of life. The disaster served as a wake-up call, highlighting the urgent need for stricter building codes, regular inspections, and improved fire escape design, all of which played a significant role in shaping modern fire safety regulations.

4. Immigrant Worker Exploitation

The Triangle Shirtwaist Factory disaster tragically highlighted the pervasive exploitation of immigrant workers in the early 20th century. Many of the victims were young, female immigrants, primarily of Italian and Eastern European Jewish descent. Their vulnerability to exploitation due to language barriers, limited employment options, and unfamiliarity with American labor laws contributed significantly to the hazardous conditions they faced and the devastating consequences of the fire.

- Low Wages and Long Hours:

Immigrant workers often endured long working hours, sometimes exceeding 12 hours a day, for meager wages. The desperate need for income made them more likely to accept dangerous working conditions and less likely to protest out of fear of losing their jobs. This economic vulnerability made them captive to exploitative employers who prioritized profits over worker safety.

- Dangerous Working Conditions:

Immigrant workers were often relegated to the most hazardous jobs, facing dangerous machinery, overcrowded workspaces, and exposure to flammable materials with minimal safety precautions. Language barriers and limited access to information about worker rights further increased their vulnerability to these unsafe conditions. The lack of adequate safety measures contributed directly to the rapid spread of the fire and the high number of casualties.

- Limited Legal Protections and Recourse:

Existing labor laws offered limited protection to immigrant workers, and language barriers and fear of reprisal often prevented them from reporting unsafe conditions or seeking legal recourse. This lack of legal protection allowed employers to operate with impunity, creating an environment where worker safety was routinely neglected.

- Social and Cultural Isolation:

Social and cultural isolation further marginalized immigrant workers, making them less likely to be aware of their rights or to have access to support systems that could advocate for their safety. This isolation compounded their vulnerability to exploitation and contributed to their acceptance of dangerous working conditions.

The exploitation of immigrant workers at the Triangle Shirtwaist Factory directly contributed to the scale of the tragedy. The disaster exposed the systemic inequalities faced by these vulnerable populations and served as a catalyst for labor reforms, including improved safety regulations, shorter working hours, and greater protections for workers’ rights. The legacy of this event continues to resonate in discussions about worker exploitation and the ongoing struggle for fair labor practices.

5. Catalyst for Labor Reform

The Triangle Shirtwaist Factory disaster stands as a pivotal moment in American labor history, serving as a tragic catalyst for widespread reform. The horrific loss of life exposed the egregious working conditions prevalent in many industries at the time and ignited public outrage, demanding immediate action to protect workers. The disaster’s aftermath led to significant legislative changes and strengthened the labor movement’s fight for improved safety regulations and worker protections.

- Increased Public Awareness and Outrage:

The sheer scale of the tragedy and the heart-wrenching stories of the victims captured national attention and sparked public outrage. Newspapers and magazines extensively covered the disaster, revealing the unsafe working conditions and the exploitation of vulnerable immigrant workers. This heightened public awareness created unprecedented pressure on lawmakers to address the urgent need for reform.

- Formation of Investigative Committees and Commissions:

The disaster prompted the formation of investigative committees and commissions to examine the causes of the fire and recommend preventative measures. The New York State Factory Investigating Commission, for example, conducted extensive investigations and public hearings, leading to a series of groundbreaking labor laws addressing fire safety, factory inspections, and working conditions.

- Strengthened Labor Unions and Advocacy Groups:

The tragedy galvanized the labor movement, empowering unions and advocacy groups to push for stronger worker protections. The International Ladies’ Garment Workers’ Union (ILGWU), in particular, gained significant momentum, advocating for improved safety standards, shorter working hours, and better wages for garment workers.

- Enactment of New Labor Laws and Safety Regulations:

The public outcry and the findings of investigative committees resulted in the enactment of significant labor laws and safety regulations at both the state and national levels. These new laws addressed fire safety, building codes, factory inspections, working hours, and child labor, marking a turning point in the fight for worker safety and rights.

The Triangle Shirtwaist Factory disaster’s legacy extends far beyond the immediate aftermath. The tragedy served as a critical turning point in American labor history, demonstrating the power of public advocacy and the profound impact of a single event on shaping national policy. The reforms spurred by the disaster laid the foundation for modern workplace safety standards and continue to inspire efforts to protect workers’ rights and ensure safe working conditions for all.

Frequently Asked Questions

The following questions and answers address common inquiries regarding the Triangle Shirtwaist Factory disaster, providing further clarity and context surrounding this pivotal event in American history.

Question 1: What were the primary causes of the high death toll in the fire?

The high death toll resulted from a combination of factors, including locked exits, inadequate fire escapes, overcrowding, highly flammable materials, and a lack of effective fire suppression systems. These factors, compounded by the panic and chaos of the situation, created a deadly trap for the workers.

Question 2: Who were the majority of the victims?

The majority of the victims were young immigrant women, primarily of Italian and Eastern European Jewish descent. These women worked long hours for low wages in dangerous conditions, highlighting the vulnerabilities of immigrant labor at the time.

Question 3: What was the immediate aftermath of the disaster?

The immediate aftermath was marked by widespread grief and outrage. Public mourning for the victims was accompanied by demands for accountability and reform. The disaster spurred investigations, legal proceedings, and ultimately, significant changes in labor laws and safety regulations.

Question 4: What specific legal and regulatory changes resulted from the disaster?

The disaster led to significant reforms in workplace safety, including improved fire safety codes, mandatory fire drills, stricter building inspections, and regulations regarding factory exits and fire escapes. These changes aimed to prevent similar tragedies from occurring in the future.

Question 5: How did the disaster impact the labor movement?

The disaster galvanized the labor movement, strengthening unions and increasing advocacy for workers’ rights. The tragedy fueled the fight for better working conditions, shorter working hours, and higher wages, leading to substantial progress in worker protections over time.

Question 6: What is the lasting legacy of the Triangle Shirtwaist Factory disaster?

The disaster’s legacy continues to shape discussions about workplace safety and workers’ rights. It serves as a stark reminder of the importance of stringent safety regulations, worker advocacy, and the ongoing need to protect vulnerable populations from exploitation. The event remains a pivotal moment in American labor history and continues to inform contemporary efforts to ensure safe and equitable working conditions for all.

Understanding the frequently asked questions surrounding this tragic event provides a deeper understanding of its historical context and enduring significance.

Continue reading to explore more about the specific individuals impacted by the Triangle Shirtwaist Factory fire and the personal stories that humanize this historical tragedy.

The Unforgettable Fire

The Triangle Shirtwaist Factory disaster remains a searing indictment of industrial negligence and a turning point in American labor history. This exploration has examined the confluence of factors that led to the tragedy: locked doors, inadequate fire escapes, flammable materials, and a regulatory environment that prioritized profit over human life. The devastating loss of 146 predominantly immigrant workers exposed the harsh realities of early 20th-century industrial practices and the exploitation of vulnerable populations. The disaster’s aftermath spurred significant reforms, including advancements in fire safety regulations, strengthened labor unions, and a heightened awareness of the importance of worker protections.

The lessons learned from this tragedy must never be forgotten. Continued vigilance regarding workplace safety, robust enforcement of regulations, and unwavering advocacy for workers’ rights remain essential to preventing similar disasters. The 146 lives lost serve as a constant reminder of the human cost of complacency and the enduring need for a society that prioritizes the safety and well-being of all workers. Their stories compel continued dedication to ensuring that such a tragedy never happens again.