Airship accidents involving large, rigid dirigibles filled with lighter-than-air gases, often hydrogen or helium, have resulted in significant loss of life and property throughout history. Examples include the burning of the Hindenburg in 1937 and the crash of the USS Akron in 1933. Such events typically involve structural failure, ignition of lifting gas, or adverse weather conditions.

Studying these incidents provides crucial insights into materials science, aeronautical engineering, and disaster preparedness. Analysis of past failures leads to improvements in design, construction, and operational procedures, enhancing the safety of future airships and other forms of transportation. Furthermore, understanding the historical context of these events offers valuable lessons about risk assessment, public perception, and the societal impact of technological advancements.

This exploration will delve into specific cases, examining the causes, consequences, and lessons learned from prominent airship accidents. It will also discuss the evolving regulatory landscape and the future of lighter-than-air travel in light of these historical events.

Airship Safety Precautions

The following precautions are crucial for mitigating risks associated with lighter-than-air travel and preventing catastrophic incidents.

Tip 1: Rigorous Material Inspections: Regular and thorough inspection of envelope materials, structural components, and gas handling systems is paramount. Non-destructive testing methods should be employed to identify weaknesses or defects before they escalate into critical failures.

Tip 2: Inert Gas Preference: Whenever feasible, helium should be the lifting gas of choice. While more expensive than hydrogen, helium’s non-flammability significantly reduces the risk of catastrophic fires.

Tip 3: Advanced Weather Monitoring: Comprehensive weather forecasting and real-time monitoring are essential. Airships should avoid operation in conditions prone to strong winds, lightning storms, or icing, which can stress the structure and compromise stability.

Tip 4: Redundant Safety Systems: Critical systems, such as control surfaces and gas valves, should incorporate redundancy to ensure continued operation in case of component failure. Backup systems enhance the resilience of the airship in unexpected situations.

Tip 5: Stringent Crew Training: Highly trained crew members are essential for safe operation. Training should cover emergency procedures, weather interpretation, and proper handling of the airship’s systems under various conditions.

Tip 6: Ground Crew Expertise: A skilled ground crew plays a vital role in safe launch and landing procedures. Proper handling of mooring lines and ground support equipment minimizes the risk of damage during these critical phases of operation.

Tip 7: Regulatory Compliance: Adherence to stringent safety regulations and certification standards is fundamental. Regular audits and inspections by regulatory bodies ensure compliance and promote a culture of safety within the industry.

Implementing these precautions significantly enhances the safety of airship operations, reducing the likelihood of accidents and protecting both crew and passengers. A proactive approach to safety management is vital for the continued development and public acceptance of lighter-than-air travel.

By learning from past incidents and embracing advanced technologies and safety protocols, the future of airship travel can be characterized by enhanced safety and reliability.

1. Structural Failure

Structural failure represents a critical factor in airship accidents. The structural integrity of an airship’s framework, including the envelope, internal bracing, and control surfaces, is essential for maintaining its shape and resisting aerodynamic forces. Compromise of this integrity can lead to catastrophic consequences. Several factors can contribute to structural failure, including material fatigue, inadequate design margins, manufacturing defects, and in-flight stresses exceeding design limitations. The consequences can range from minor damage to complete loss of control and catastrophic collapse. The R101 crash in 1930 exemplifies a structural failure attributed to a combination of design deficiencies and adverse weather conditions. The weakened framework was unable to withstand the stresses encountered during flight, ultimately leading to its disintegration.

Understanding the mechanics of structural failure is crucial for enhancing airship safety. Thorough stress analysis during the design phase, rigorous material selection, and stringent quality control during manufacturing are essential for minimizing the risk of structural failure. Regular inspections and non-destructive testing can identify potential weaknesses before they develop into catastrophic failures. Furthermore, operational procedures should account for stress limitations and avoid maneuvers that could overstress the airship’s structure. Advanced materials and construction techniques can contribute to stronger and more resilient airship designs, further mitigating the risk of structural failure.

Addressing structural failure remains a key challenge in ensuring the safety and reliability of airships. Advances in structural engineering, materials science, and predictive modeling contribute to improved designs and operational practices. By incorporating lessons learned from past accidents and adopting a proactive approach to safety, the likelihood of structural failures can be significantly reduced, paving the way for a safer future for airship travel. Further research and development in this area are essential for the continued advancement of airship technology and the restoration of public confidence in its safety.

2. Gas Leaks/Ignition

Gas leaks and subsequent ignition represent a significant hazard in airship operation, often leading to catastrophic consequences. The use of flammable lifting gases, such as hydrogen, historically posed a substantial risk. A leak, even a small one, could create a volatile mixture with the surrounding air, susceptible to ignition from various sources, including static electricity, electrical faults, or open flames. The rapid combustion of a large volume of hydrogen, as tragically demonstrated by the Hindenburg disaster, can result in a devastating explosion and fire. Even modern airships using non-flammable helium are not entirely immune to fire-related risks. While the lifting gas itself won’t ignite, flammable materials within the airship’s structure can still be ignited by electrical faults or other sources. The resulting fires, if not contained quickly, can compromise structural integrity, potentially leading to a catastrophic failure.

Understanding the dynamics of gas leaks and ignition is crucial for mitigating risks in airship operations. Rigorous leak detection systems, coupled with robust fire suppression measures, are essential safety components. Material selection for interior components should prioritize fire resistance. Stringent protocols for handling flammable materials during maintenance and operation are equally important. Furthermore, ongoing research into advanced materials and fire suppression technologies offers the potential for further enhancements in airship safety. The shift towards helium as the preferred lifting gas has significantly reduced the risk of large-scale explosions, but fire hazards related to onboard materials remain a concern that demands continuous attention.

Mitigating the risk of gas leaks and ignition requires a multi-pronged approach encompassing design, materials, operational procedures, and ongoing technological advancements. Learning from historical accidents, like the Hindenburg, reinforces the critical importance of minimizing the presence of flammable materials and implementing robust fire safety measures. Continued vigilance and advancements in fire suppression technologies are paramount for ensuring the future safety and viability of airship travel.

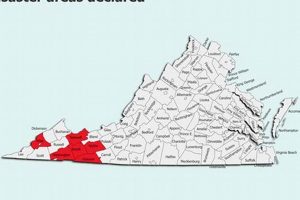

3. Adverse Weather

Adverse weather conditions represent a significant contributing factor to airship accidents. Wind gusts, thunderstorms, icing, and poor visibility can impose substantial stresses on an airship’s structure and complicate navigation. Strong winds can exceed the airship’s control authority, leading to loss of control and potential collisions with obstacles or the ground. Lightning strikes pose a direct threat, potentially igniting flammable lifting gases or damaging sensitive electronic equipment. Icing accumulates on the airship’s surface, adding weight and disrupting airflow, further compromising stability and control. The USS Akron, for instance, encountered severe weather conditions during a transatlantic flight in 1933. Caught in a powerful storm, the airship’s structure was overstressed, leading to its tragic demise.

Understanding the impact of adverse weather on airship operations is crucial for enhancing safety. Pre-flight weather briefings and continuous monitoring during flight are essential. Airship routes should be planned to avoid areas known for turbulent conditions. Operational limitations should define acceptable wind speeds, visibility, and other meteorological parameters. Advancements in weather forecasting and real-time monitoring technologies provide valuable tools for mitigating weather-related risks. Furthermore, equipping airships with robust de-icing systems and lightning protection mechanisms can enhance their resilience in challenging weather conditions. The development of improved structural designs capable of withstanding higher wind loads and turbulence represents another crucial area of ongoing research.

Mitigating the risks associated with adverse weather requires a combination of advanced technology, rigorous operational procedures, and ongoing research into airship design and materials. Learning from past accidents, such as the USS Akron disaster, emphasizes the critical importance of respecting weather limitations and adopting a proactive approach to safety management. Continued advancements in weather prediction and risk assessment, combined with robust structural design, are crucial for ensuring the safety and reliability of airship operations in diverse weather conditions.

4. Human Error

Human error represents a significant contributing factor to airship accidents, often acting as the catalyst for a chain of events leading to disaster. Misjudgments in navigation, improper handling of controls, inadequate pre-flight inspections, and flawed decision-making during emergencies can all have catastrophic consequences. The human element introduces variability and unpredictability into a complex system, increasing the likelihood of errors, particularly under stressful conditions. For example, the R101 disaster, while partially attributed to structural weaknesses, was also influenced by the pressure to proceed with the flight despite known technical issues and unfavorable weather forecasts. This decision, driven by political and economic considerations, ultimately contributed to the tragic outcome. Similarly, inadequate crew training or insufficient adherence to established safety procedures can exacerbate existing risks, transforming minor incidents into major catastrophes.

Understanding the role of human error in airship accidents is crucial for developing effective mitigation strategies. Comprehensive training programs, emphasizing both technical skills and decision-making under pressure, are essential. Clear communication protocols, standardized procedures, and checklists can reduce ambiguity and minimize the potential for errors. Promoting a culture of safety, where reporting near misses and potential hazards is encouraged, can provide valuable insights for preventing future accidents. Human factors analysis, a systematic approach to understanding human capabilities and limitations, can inform the design of airship systems and operational procedures, reducing the likelihood of errors. Furthermore, implementing robust oversight and regulatory frameworks can enforce adherence to safety standards and best practices.

Addressing the human element remains a critical challenge in ensuring airship safety. While technological advancements can improve system reliability and resilience, human actions remain a significant source of variability. Learning from past accidents, where human error played a decisive role, underscores the importance of comprehensive training, clear procedures, and a proactive safety culture. Continued focus on human factors research and the implementation of robust safety management systems are essential for mitigating the risks associated with human error and enhancing the safety of airship operations.

5. Inadequate Design

Inadequate design represents a critical vulnerability in airship construction, increasing the likelihood of catastrophic incidents. Design flaws can manifest in various forms, including insufficient structural strength, inadequate control surface area, improper weight distribution, or flawed gas cell construction. Such deficiencies can compromise the airship’s structural integrity, aerodynamic stability, or gas retention capabilities, rendering it susceptible to failure under stress. For instance, the R101, a British airship, suffered a catastrophic crash in 1930 due in part to design shortcomings. Its gas cells were known to leak, and the overall structure lacked sufficient strength to withstand the stresses encountered during flight. These design flaws, combined with adverse weather conditions, ultimately led to the airship’s disintegration and the loss of nearly all onboard.

A thorough understanding of the impact of inadequate design is crucial for preventing future airship disasters. Rigorous design reviews, incorporating comprehensive stress analysis and wind tunnel testing, are essential for identifying and rectifying potential weaknesses before construction. Furthermore, adherence to stringent airworthiness standards and certification processes can help ensure that design flaws are identified and addressed prior to operation. Learning from historical accidents, such as the R101 disaster, highlights the importance of prioritizing robust design principles and incorporating safety margins to account for unforeseen circumstances. The evolution of computer-aided design and simulation tools offers significant opportunities for enhancing design accuracy and validating structural integrity before an airship ever takes flight. These advanced tools enable engineers to analyze complex stress distributions, model aerodynamic behavior, and optimize weight distribution with greater precision, leading to safer and more reliable airship designs.

Addressing inadequate design requires a multi-faceted approach encompassing rigorous engineering analysis, stringent regulatory oversight, and a commitment to continuous improvement. Historical airship disasters underscore the tragic consequences of design flaws and emphasize the need for robust design principles, thorough testing, and adherence to stringent safety standards. By incorporating lessons learned from the past and embracing advanced design tools, the airship industry can strive towards a future where design-related failures are minimized, paving the way for safer and more reliable airship operations.

6. Lack of Safety Procedures

The absence or inadequacy of established safety procedures significantly contributes to the risk of blimp disasters. Well-defined protocols, encompassing all aspects of airship operation, from design and construction to maintenance and flight procedures, are essential for mitigating risks and preventing accidents. A lack of such procedures creates an environment where hazards can escalate unchecked, potentially leading to catastrophic consequences.

- Ground Handling Procedures:

Clear ground handling procedures are crucial for minimizing risks during mooring, inflation, and other ground operations. Without specific protocols, mishandling of mooring lines, improper inflation techniques, or inadequate ground crew training can create hazards, potentially damaging the airship or causing accidents. The absence of standardized procedures increases the likelihood of human error and jeopardizes the safety of ground personnel and the airship itself.

- Emergency Procedures:

Well-defined emergency procedures are essential for mitigating the consequences of unexpected events, such as engine failure, gas leaks, or fire. Without pre-established protocols, crew responses can be delayed, disorganized, or ineffective, exacerbating the situation. Comprehensive emergency procedures, including fire drills, evacuation protocols, and emergency landing procedures, are crucial for enhancing crew preparedness and minimizing the impact of emergencies.

- Maintenance Procedures:

Stringent maintenance procedures are vital for ensuring the airworthiness of the blimp. Regular inspections, adhering to established maintenance schedules, and detailed documentation of repairs are essential for identifying and addressing potential problems before they escalate into major safety hazards. A lack of standardized maintenance procedures increases the likelihood of overlooked defects, inadequate repairs, and ultimately, increased risk of in-flight failures.

- Flight Operations Procedures:

Clearly defined flight operations procedures, encompassing pre-flight checks, weather limitations, altitude restrictions, and communication protocols, are fundamental for safe operation. Without standardized procedures, pilots may make improper judgments regarding weather conditions, exceed operational limits, or experience communication breakdowns, all of which can contribute to accidents. Well-defined flight operation procedures promote consistency, reduce ambiguity, and minimize the risk of human error during critical phases of flight.

The absence of comprehensive safety procedures across these crucial areas creates a vulnerable operational environment. Such deficiencies increase the likelihood of human error, equipment malfunction, and inadequate responses to emergencies, contributing significantly to the risk of blimp disasters. Prioritizing the development and implementation of robust safety protocols is essential for ensuring the safety and long-term viability of airship operations.

7. Insufficient Maintenance

Insufficient maintenance contributes directly to the risk of blimp disasters. Neglecting routine inspections, deferring necessary repairs, and failing to adhere to established maintenance schedules can compromise the structural integrity of the airship, increase the likelihood of mechanical failures, and create conditions conducive to accidents. Airships, by their nature, operate in demanding environments, subject to significant stress and strain. Regular maintenance is essential for identifying and addressing wear and tear, corrosion, fatigue, and other potential issues before they escalate into catastrophic failures. For example, neglecting to inspect and repair minor tears in the envelope fabric can lead to larger tears, potentially culminating in a complete rupture and loss of lift. Similarly, failure to properly lubricate moving parts or inspect engine components can result in mechanical malfunctions, potentially leading to loss of control or other critical failures. The lack of proper documentation of maintenance activities further compounds the problem, hindering the ability to track component lifecycles, identify recurring issues, and ensure that all necessary maintenance tasks are performed.

The consequences of insufficient maintenance can be particularly severe in the context of blimp operations. Unlike fixed-wing aircraft, which can often glide to a safe landing in the event of engine failure, blimps rely on buoyancy for sustained flight. A structural failure or loss of lifting gas can have immediate and catastrophic consequences. The Hindenburg disaster, while primarily attributed to the ignition of the flammable hydrogen lifting gas, was also influenced by maintenance issues related to the airship’s outer covering. The deterioration of the fabric, combined with inadequate patching and repair, likely contributed to the rapid spread of the fire. This tragic event underscores the critical importance of meticulous maintenance in preventing blimp disasters.

Addressing the risks associated with insufficient maintenance requires a multi-faceted approach. Establishing and adhering to rigorous maintenance schedules, based on manufacturer recommendations and operational experience, is fundamental. Thorough documentation of all maintenance activities provides a crucial record for tracking component condition and ensuring compliance with established procedures. Investing in training and certification programs for maintenance personnel ensures that they possess the necessary skills and knowledge to perform their duties effectively. Furthermore, fostering a culture of safety, where reporting potential maintenance issues is encouraged and addressed promptly, can contribute significantly to preventing accidents. Insufficient maintenance represents a critical vulnerability in blimp operations, and a proactive approach to maintenance management is essential for ensuring safety and preventing disasters.

Frequently Asked Questions About Blimp Accidents

This section addresses common inquiries regarding the safety of lighter-than-air travel, focusing on historical incidents and the lessons learned to prevent future disasters.

Question 1: What caused the Hindenburg disaster?

While the exact ignition source remains debated, the rapid combustion of the Hindenburg’s hydrogen lifting gas resulted in the disaster. The flammable nature of hydrogen contributed significantly to the fire’s intensity and rapid spread. The incident underscored the inherent dangers of using flammable lifting gases in airships.

Question 2: Are modern blimps safer than those of the past?

Modern blimps benefit from significant advancements in materials science, design, and operational procedures. The use of non-flammable helium as a lifting gas, coupled with improved fire-resistant materials and stringent safety regulations, significantly enhances the safety profile of contemporary airships compared to their historical counterparts.

Question 3: What are the primary risks associated with blimp travel today?

While significantly safer than in the past, modern blimps still face potential risks, including adverse weather conditions, structural failure due to material fatigue or stress, and human error in operation or maintenance. Ongoing efforts focus on mitigating these risks through improved design, stringent safety protocols, and advanced weather monitoring systems.

Question 4: What safety regulations govern blimp operations?

Various national and international regulatory bodies oversee blimp operations, establishing standards for design, construction, maintenance, and operation. These regulations aim to ensure a high level of safety and minimize the risk of accidents.

Question 5: How are lessons from past blimp disasters incorporated into current practices?

Analysis of past accidents provides invaluable insights into potential vulnerabilities and informs current safety practices. Lessons learned have led to improvements in design, materials selection, operational procedures, and emergency protocols, contributing to the enhanced safety of modern airships.

Question 6: What is the future of blimp travel?

The future of blimp travel hinges on continued advancements in safety and technology. Research into new materials, propulsion systems, and operational procedures may contribute to increased efficiency, reduced environmental impact, and enhanced safety, potentially revitalizing interest in airships for various applications, such as cargo transport, tourism, and surveillance.

Continuously refining safety measures and learning from past incidents are paramount for ensuring the safety and future viability of airship technology. This commitment to improvement fosters public confidence and promotes the responsible development of lighter-than-air travel.

The following section will delve into specific case studies of historical blimp accidents, providing a detailed analysis of their causes, consequences, and the lessons learned.

Conclusion

Airship accidents, often resulting in significant loss of life and property, underscore the complex interplay of design, materials, operational procedures, and environmental factors in aviation safety. From the Hindenburg’s fiery demise to the structural failures of airships like the R101 and USS Akron, history provides critical lessons about the importance of rigorous engineering, stringent safety protocols, and continuous vigilance. Examination of these events reveals recurring themes: inadequate design margins, flammable materials, vulnerability to adverse weather, human error, and insufficient maintenance. Addressing these vulnerabilities remains crucial for ensuring the safety and reliability of lighter-than-air travel.

The legacy of these accidents should serve as a constant reminder of the imperative for proactive safety management in airship operations. Continued advancements in materials science, structural engineering, and operational practices are essential for minimizing risks and preventing future tragedies. Only through meticulous attention to detail, a commitment to learning from past failures, and a steadfast dedication to safety can the potential of lighter-than-air technology be realized while safeguarding human life and preventing further airship disasters.