The December 1984 incident at the Union Carbide India Limited pesticide plant remains one of the world’s worst industrial catastrophes. A leak of methyl isocyanate (MIC) gas resulted in the immediate deaths of thousands and exposed over half a million people to toxic substances. The event’s devastation extended far beyond the initial impact, causing long-term health issues including respiratory problems, eye damage, and neurological disorders across generations.

This tragedy serves as a critical case study in industrial safety, environmental regulation, and corporate responsibility. It highlighted the potential consequences of inadequate safety protocols, insufficient emergency preparedness, and the complex ethical dilemmas surrounding industrial development in densely populated areas. The disaster spurred significant changes in global industrial safety standards and prompted renewed focus on the rights of victims in industrial accidents. Its legacy continues to shape discussions on environmental justice and disaster preparedness worldwide.

Further exploration of this incident will cover the specific technical failures that led to the leak, the immediate and long-term health impacts on the affected population, the legal and political ramifications, and the ongoing efforts to provide medical care and remediation to the survivors and their families.

Lessons for Preventing Future Industrial Tragedies

The Bhopal disaster provides invaluable, albeit tragic, lessons for industries and governments worldwide. Understanding the circumstances that led to this catastrophe can help prevent similar incidents in the future.

Tip 1: Rigorous Safety Protocols: Implement and strictly enforce comprehensive safety protocols for hazardous materials, including regular inspections, maintenance, and employee training. Redundant safety systems should be standard practice.

Tip 2: Emergency Preparedness: Develop and regularly practice detailed emergency response plans involving local communities and authorities. Clear communication channels and accessible medical resources are essential.

Tip 3: Corporate Accountability: Establish clear lines of responsibility for industrial safety and environmental protection. Companies must prioritize safety over profit and be held accountable for negligence.

Tip 4: Government Oversight: Regulatory bodies must enforce strict environmental and safety regulations, conduct thorough inspections, and ensure transparency in industrial operations.

Tip 5: Community Engagement: Open communication and collaboration between industries, local communities, and authorities are crucial. Communities must have access to information about potential risks and be involved in safety planning.

Tip 6: Long-Term Health Monitoring: Establish long-term health monitoring programs for populations exposed to industrial chemicals to understand and address the chronic health effects of such exposures.

Tip 7: International Cooperation: Foster international collaboration on industrial safety standards and best practices to ensure consistent levels of protection globally. Sharing information and resources can prevent similar tragedies.

Adopting these preventative measures is vital for protecting communities and the environment from industrial hazards. The Bhopal disaster serves as a constant reminder of the devastating consequences of inadequate safety practices and the importance of prioritizing human well-being and environmental protection.

Understanding the lessons learned from Bhopal paves the way for a safer and more sustainable industrial future. Continued vigilance and commitment are essential to prevent such a tragedy from ever happening again.

1. Methyl Isocyanate (MIC) Leak

The methyl isocyanate (MIC) leak lies at the heart of the Bhopal disaster. Understanding the properties of MIC and the circumstances surrounding its release is crucial for comprehending the scale and impact of the tragedy.

- Toxicity of MIC

MIC is a highly toxic substance. Exposure to even small concentrations can cause severe respiratory irritation, pulmonary edema, and death. The high volatility of MIC meant the gas rapidly spread through the surrounding densely populated areas, leading to widespread exposure and immediate fatalities.

- Circumstances of the Leak

Multiple factors contributed to the leak, including inadequate safety systems, maintenance failures, and operational errors. Water entering a storage tank containing MIC triggered a runaway exothermic reaction, resulting in a rapid build-up of pressure and the subsequent release of large quantities of toxic gas into the atmosphere.

- Spread and Impact of the Gas Cloud

The dense gas cloud, heavier than air, spread quickly through the surrounding residential areas, impacting a vast population. The lack of adequate warning systems and emergency preparedness exacerbated the situation, contributing to the high casualty rate and long-term health consequences.

- Long-Term Health Effects

Survivors of the MIC leak experienced a range of chronic health problems, including respiratory illnesses, eye damage, neurological disorders, and psychological trauma. The disaster’s long-term health impacts continue to affect survivors and subsequent generations, highlighting the profound consequences of exposure to toxic chemicals.

The MIC leak at Bhopal serves as a stark reminder of the inherent dangers associated with hazardous chemicals. This incident underscores the critical need for robust safety protocols, effective emergency response plans, and ongoing medical support for affected populations. Understanding the specific properties of MIC, the circumstances of its release, and the widespread health consequences provides crucial insights into the magnitude of the Bhopal disaster and the importance of preventing similar incidents in the future.

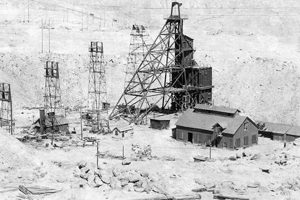

2. Union Carbide India Limited

Union Carbide India Limited (UCIL), a subsidiary of the American Union Carbide Corporation, operated the pesticide plant in Bhopal where the disaster occurred. The company’s role in the tragedy is central to understanding the complex interplay of factors that led to the catastrophic event. UCIL’s operational practices, safety standards, and emergency preparedness measures are key areas of scrutiny when analyzing the disaster’s root causes.

Investigations revealed cost-cutting measures at the UCIL plant, including reduced staffing, deferred maintenance, and inadequate training of personnel. These factors likely compromised the plant’s safety systems and contributed to the conditions that allowed the leak to occur. Furthermore, UCIL’s emergency response proved insufficient to contain the spread of the toxic gas or mitigate its impact on the surrounding population. The lack of effective communication and coordination between the company and local authorities exacerbated the crisis. The disaster raised serious questions about the responsibility of multinational corporations operating in developing countries and the adequacy of regulatory oversight.

The legal and ethical implications of UCIL’s role in the Bhopal disaster continue to be debated. While settlements were reached, and funds were allocated for remediation and victim compensation, the long-term consequences of the disaster persist. The Bhopal tragedy underscores the critical importance of corporate responsibility, robust safety regulations, and effective emergency preparedness in the chemical industry. It serves as a cautionary tale about the potential human and environmental costs of prioritizing profits over safety.

3. December 1984

December 1984 marks the specific timeframe of the Bhopal gas tragedy, a pivotal moment in industrial history. Understanding the context of this period is essential for comprehending the societal, environmental, and regulatory landscape in which the disaster unfolded and its subsequent impact.

- The Night of the Disaster

The leak began late on the night of December 2nd, 1984, quickly engulfing the surrounding areas in a toxic cloud of methyl isocyanate (MIC) gas. This specific timing, when many residents were asleep, contributed significantly to the high number of casualties and the widespread panic that ensued.

- Immediate Aftermath and Response

The immediate days and weeks following the leak in December 1984 were marked by chaos and confusion. Thousands of people died in the immediate aftermath, and many more suffered acute health effects. The initial response was hampered by a lack of preparedness and understanding of the scale and severity of the disaster.

- Investigation and Legal Proceedings

Throughout December 1984 and the following years, investigations into the cause of the disaster began, and legal proceedings were initiated. These early efforts to determine accountability and provide compensation to victims were crucial in shaping the long-term legal and political ramifications of the tragedy.

- Global Impact and Legacy

The events of December 1984 in Bhopal resonated globally, prompting increased scrutiny of industrial safety standards and corporate responsibility. The disaster served as a catalyst for changes in regulations and practices worldwide, impacting how hazardous materials are handled and stored, and how industrial accidents are addressed.

The specific context of December 1984 provides critical insight into the Bhopal disaster. From the timing of the leak to the initial response and the long-term consequences, understanding this period is essential for comprehending the magnitude of the tragedy and its lasting impact on industrial safety, environmental regulations, and the pursuit of justice for victims of industrial accidents.

4. Industrial Negligence

Industrial negligence played a significant role in the Bhopal disaster. Multiple factors point to a disregard for safety protocols and a prioritization of cost-cutting measures over the well-being of workers and the surrounding community. These factors contributed directly to the circumstances that allowed the methyl isocyanate (MIC) leak to occur and exacerbated its devastating impact.

Several key examples of negligence include deferred maintenance of critical safety systems, inadequate training of personnel handling hazardous materials, and insufficient staffing levels to ensure proper oversight of plant operations. The refrigeration unit designed to cool the MIC tank was deactivated, and the vent gas scrubber, intended to neutralize escaping MIC, was malfunctioning. Furthermore, the flare tower, a last resort safety measure designed to burn off escaping gas, was also inoperative. These failures, coupled with a lack of proper safety audits and emergency preparedness drills, created a vulnerable environment ripe for disaster.

The Bhopal disaster serves as a stark illustration of the devastating consequences of industrial negligence. The incident highlighted the critical need for stringent safety regulations, robust oversight of industrial operations, and a culture of prioritizing safety over profits. Understanding the role of negligence in the Bhopal tragedy emphasizes the importance of proactive safety measures, corporate accountability, and the ethical obligation of industries to protect their workers and surrounding communities. The legacy of Bhopal continues to shape discussions about industrial safety and environmental justice, driving efforts to prevent similar tragedies from occurring in the future.

5. Long-term health impacts

The 1984 Bhopal gas tragedy resulted in a devastating spectrum of long-term health problems for those exposed to the released methyl isocyanate (MIC). These chronic conditions continue to affect survivors and subsequent generations, underscoring the profound and enduring consequences of the disaster. The release of MIC caused immediate and severe damage to the respiratory system, leading to chronic bronchitis, emphysema, and persistent lung infections. Ocular damage, including cataracts, glaucoma, and chronic conjunctivitis, also emerged as a significant long-term health issue.

Beyond the immediate physical effects, the disaster also had a profound impact on neurological health. Survivors experienced a range of neurological disorders, including memory loss, numbness, tremors, and depression. Furthermore, the disaster led to an increase in birth defects and reproductive health problems in the affected population, adding another layer of complexity to the long-term health challenges. The chronic nature of these health problems necessitates ongoing medical care and support for survivors, placing a significant burden on healthcare systems and impacting the socioeconomic well-being of affected communities.

The long-term health impacts of the Bhopal disaster highlight the importance of comprehensive medical monitoring and long-term support for survivors of chemical disasters. The experience of Bhopal underscores the need for preventative measures in industrial settings to minimize the risk of such incidents and the importance of adequate healthcare infrastructure and resources to address the complex and enduring health needs of affected populations. The ongoing health challenges faced by Bhopal survivors serve as a stark reminder of the human cost of industrial disasters and the imperative to prioritize safety and environmental protection.

6. Environmental Contamination

The Bhopal disaster resulted in severe and long-lasting environmental contamination, significantly impacting the local ecosystem and the health of surrounding communities. The release of methyl isocyanate (MIC), along with other toxic byproducts, contaminated the soil, water, and air. This contamination persisted for years, leading to a range of environmental and health problems.

Soil samples taken from the area surrounding the Union Carbide plant revealed high concentrations of MIC and its degradation products. This contamination affected agricultural land, rendering it unsuitable for cultivation and impacting local food production. Groundwater contamination also posed a serious threat, as toxic chemicals leached into the water table, affecting drinking water sources and posing risks to human health. The air pollution caused by the release of MIC and other volatile organic compounds led to respiratory problems and other health issues in the immediate aftermath of the disaster and continued to pose risks long after the initial incident.

The environmental contamination resulting from the Bhopal disaster serves as a stark example of the long-term ecological damage that can result from industrial accidents. This contamination continues to impact the local environment and the health of communities in Bhopal, underscoring the critical need for robust environmental regulations, preventative safety measures in industrial operations, and effective remediation strategies to address the long-term consequences of chemical disasters. The Bhopal disaster highlights the interconnectedness of industrial safety, environmental protection, and public health, and the importance of proactive measures to mitigate the risks of such catastrophic events.

Frequently Asked Questions

This FAQ section addresses common questions about the Bhopal disaster, providing concise and informative answers.

Question 1: What exactly happened in Bhopal, India, in 1984?

A large-scale industrial disaster occurred at the Union Carbide India Limited (UCIL) pesticide plant in Bhopal, India, on December 2-3, 1984. A leak of methyl isocyanate (MIC) gas, a highly toxic chemical used in pesticide production, spread throughout the surrounding densely populated areas, resulting in thousands of immediate deaths and long-term health problems for hundreds of thousands more.

Question 2: What caused the MIC leak?

Investigations point to a combination of factors, including water entering an MIC storage tank, which triggered a runaway chemical reaction. This, coupled with inadequate safety systems, maintenance failures, and operational errors, led to the release of large quantities of MIC gas.

Question 3: What were the immediate and long-term health consequences of the disaster?

The immediate effects included burning eyes, coughing, vomiting, and difficulty breathing, leading to thousands of fatalities. Long-term health problems experienced by survivors include chronic respiratory illnesses, eye damage, neurological disorders, and increased risks of cancer and birth defects.

Question 4: What was the response to the disaster?

The initial response was chaotic and hampered by a lack of preparedness. Subsequent efforts focused on medical treatment, victim compensation, and environmental remediation. The disaster led to significant changes in industrial safety regulations and practices worldwide.

Question 5: What is the current status of the affected area and its residents?

While some remediation efforts have been undertaken, the area still faces long-term environmental and health challenges. Many survivors continue to experience health problems, and the disaster’s impact persists across generations. Ongoing efforts focus on providing medical care, rehabilitation, and social support to affected communities.

Question 6: What lessons were learned from the Bhopal disaster?

The Bhopal disaster highlighted the critical importance of stringent industrial safety regulations, rigorous safety protocols, effective emergency preparedness plans, corporate responsibility, and government oversight. It serves as a stark reminder of the potential human and environmental consequences of industrial negligence.

Understanding the Bhopal disaster remains crucial for preventing similar tragedies. Continuous vigilance and a commitment to safety and environmental protection are essential in all industrial settings.

For further information, explore resources dedicated to documenting the disaster and its ongoing impact. Academic journals, documentaries, and organizations working with affected communities offer valuable insights.

The Bhopal Chemical Disaster

The chemical disaster in Bhopal, India, serves as a sobering reminder of the devastating consequences of industrial negligence and the enduring impact of such tragedies on human lives and the environment. This exploration has examined the incident’s key aspects, from the technical failures that led to the methyl isocyanate (MIC) leak to the long-term health and environmental consequences. The disaster’s legacy continues to shape discussions on industrial safety, corporate accountability, and environmental justice worldwide. The insufficient emergency preparedness, delayed medical response, and prolonged legal battles underscore the complex challenges in addressing industrial disasters of this magnitude.

Bhopal remains a potent symbol of the urgent need for proactive safety measures, stringent regulations, and ethical corporate practices. The lessons learned from this catastrophe must continue to inform industrial processes and policies globally, ensuring that such a tragedy is never repeated. Continued vigilance, community engagement, and a commitment to prioritizing human well-being and environmental protection are essential to preventing future industrial disasters and mitigating their potential consequences.