The December 1984 incident at the Union Carbide India Limited pesticide plant in Bhopal, India, remains one of the world’s most devastating industrial accidents. The accidental release of methyl isocyanate (MIC) gas into the atmosphere exposed hundreds of thousands of people to highly toxic chemicals. The immediate consequences included widespread respiratory distress, burning eyes, and vomiting. The long-term effects continue to impact the health and well-being of survivors and their descendants, including chronic respiratory illnesses, eye problems, and birth defects.

This event serves as a stark reminder of the potential for catastrophic consequences when industrial safety protocols fail. It underscores the importance of rigorous safety regulations, thorough emergency preparedness plans, and the ethical responsibility of corporations to safeguard surrounding communities. The tragedy prompted significant changes in industrial safety practices globally and highlighted the need for greater accountability within the chemical industry. The disaster’s impact also extended to legal and ethical discussions surrounding corporate liability, environmental justice, and the right to a safe and healthy environment.

Further exploration of this event involves understanding the specific technical failures that led to the gas leak, examining the immediate and long-term health impacts on the affected population, and analyzing the legal and political ramifications of the disaster. Investigation into the disaster’s social, economic, and environmental consequences also provides crucial lessons for preventing future tragedies.

Lessons from Bhopal

The Bhopal disaster provides invaluable lessons for preventing future industrial tragedies. Implementing robust safety measures, fostering transparency, and prioritizing community well-being are crucial for responsible industrial practices. The following points highlight key takeaways:

Tip 1: Rigorous Safety Audits and Protocols: Regular, independent audits of industrial facilities handling hazardous materials are essential. These audits should assess potential hazards, evaluate safety procedures, and ensure compliance with industry best practices and regulatory requirements.

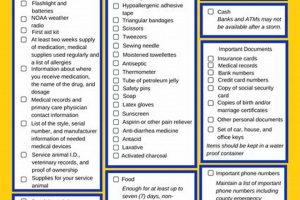

Tip 2: Comprehensive Emergency Response Plans: Detailed and well-rehearsed emergency response plans must be in place to address potential accidents. These plans should include clear communication protocols, evacuation procedures, and access to appropriate medical treatment for affected communities.

Tip 3: Transparency and Community Engagement: Open communication between industrial facilities and surrounding communities is vital. This includes sharing information about potential risks, safety procedures, and emergency response plans, fostering trust and enabling community members to participate in safety discussions.

Tip 4: Stringent Regulatory Oversight: Effective government oversight plays a crucial role in ensuring industrial safety. Regulations should establish clear safety standards, mandate regular inspections, and enforce penalties for non-compliance.

Tip 5: Corporate Accountability and Ethical Practices: Companies handling hazardous materials must prioritize safety and environmental protection. This includes investing in safety measures, promoting a culture of safety, and taking responsibility for the well-being of surrounding communities.

Tip 6: Ongoing Research and Development: Continuous research into safer alternatives to hazardous materials and the development of improved safety technologies are crucial for minimizing risks.

Tip 7: International Collaboration and Information Sharing: Global collaboration and information sharing on industrial safety practices and lessons learned from past incidents are essential for preventing future disasters.

By learning from the Bhopal tragedy, industries and governments can work together to create safer industrial environments and protect communities from the devastating consequences of industrial accidents. These lessons emphasize the importance of proactive safety measures, responsible industrial practices, and a commitment to safeguarding human lives and the environment.

The Bhopal disaster serves as a permanent call to action, urging continued vigilance and commitment to preventing future tragedies.

1. Methyl Isocyanate (MIC) Leak

The release of methyl isocyanate (MIC) gas lies at the heart of the Bhopal industrial disaster. MIC, a highly toxic chemical used in pesticide production, reacted with water inside a storage tank, generating excessive heat and pressure. This led to the rupture of a safety valve and the subsequent release of a large cloud of MIC gas into the atmosphere. The immediate effects of exposure were devastating, causing widespread respiratory distress, burning eyes, and skin irritation. The long-term health consequences continue to affect survivors and their descendants, manifesting as chronic respiratory illnesses, neurological damage, and birth defects.

The incident underscores the inherent dangers of handling hazardous chemicals like MIC. The Bhopal tragedy demonstrates the importance of stringent safety protocols, robust storage and handling procedures, and comprehensive emergency response plans. The disaster’s aftermath led to stricter regulations regarding the production, storage, and transportation of hazardous chemicals worldwide. The incident also highlights the need for effective monitoring systems, regular safety inspections, and employee training to mitigate potential risks associated with hazardous materials.

Understanding the specific role of the MIC leak in the Bhopal disaster provides crucial lessons for preventing similar tragedies. The incident emphasizes the need for comprehensive risk assessments, thorough safety audits, and a culture of safety within industrial facilities. It also highlights the ethical responsibility of corporations to protect their employees and surrounding communities from the potential dangers of industrial processes involving hazardous materials. The Bhopal disaster stands as a stark reminder of the importance of prioritizing safety and the devastating consequences that can arise from inadequate safety measures and negligence.

2. Union Carbide India Limited

Union Carbide India Limited (UCIL), a subsidiary of the American chemical company Union Carbide Corporation (UCC), operated the pesticide plant in Bhopal where the tragic gas leak occurred in December 1984. Understanding UCIL’s role is crucial for comprehending the context of the disaster, the subsequent legal battles, and the long-term implications for corporate accountability.

- Plant Ownership and Operation

UCIL owned and operated the Bhopal plant, responsible for its day-to-day functioning, safety protocols, and maintenance. The plant manufactured pesticides using MIC, a highly toxic chemical. UCIL’s operational practices and safety measures became central to investigations following the disaster, raising questions about cost-cutting measures and their potential contribution to the tragedy.

- Safety Standards and Procedures

The adequacy of safety standards and procedures implemented by UCIL at the Bhopal plant came under intense scrutiny after the gas leak. Investigations revealed concerns regarding maintenance, training, and emergency response preparedness. The disaster highlighted the critical importance of rigorous safety protocols in industrial facilities handling hazardous materials and the potential consequences of inadequate safety measures.

- Legal and Corporate Responsibility

The Bhopal disaster triggered complex legal battles involving UCIL, UCC, the Indian government, and the victims. Determining liability and ensuring just compensation for the victims became a protracted and contentious process. The case raised fundamental questions about corporate accountability, particularly in multinational operations, and the legal frameworks for addressing industrial disasters with transboundary implications.

- Long-Term Impact and Legacy

The Bhopal disaster continues to impact the health and well-being of survivors and their descendants. The long-term consequences serve as a constant reminder of the human cost of industrial negligence. The tragedy continues to influence discussions surrounding industrial safety, corporate responsibility, and environmental justice, shaping policies and practices aimed at preventing future disasters.

The role of UCIL in the Bhopal gas tragedy serves as a case study in the complex interplay of industrial operations, safety regulations, corporate responsibility, and the devastating consequences of industrial accidents. The disaster’s legacy continues to shape discussions on corporate accountability, environmental justice, and the ethical obligations of companies operating in hazardous industries. The Bhopal tragedy emphasizes the enduring need for vigilance, stringent safety measures, and a commitment to prioritizing human lives and environmental protection.

3. December 1984

December 1984 marks the specific timeframe of the Bhopal gas tragedy, forever etching this period into history as a moment of profound industrial disaster. The early hours of December 3rd, 1984, witnessed the catastrophic release of methyl isocyanate (MIC) gas from the Union Carbide India Limited pesticide plant. This precise timing is crucial for understanding the sequence of events leading to the tragedy, the immediate aftermath, and the subsequent long-term consequences. The date signifies not just the occurrence of the disaster but also the beginning of a long struggle for justice, medical care, and environmental remediation for the affected community. Pinpointing the disaster within December 1984 provides a critical temporal anchor for all subsequent analyses, investigations, and commemorative activities.

The significance of December 1984 extends beyond merely marking the date of the disaster. It represents a turning point in industrial safety awareness and regulatory oversight. The tragedy exposed critical gaps in safety protocols, emergency preparedness, and corporate accountability. The events of December 1984 served as a catalyst for significant changes in industrial practices and regulations globally, prompting a heightened focus on preventing similar disasters. The date therefore holds symbolic weight, representing a historical marker for a global shift in perspectives on industrial safety and the ethical responsibilities of corporations.

Understanding the connection between December 1984 and the Bhopal gas tragedy is essential for learning from the past and preventing future catastrophes. Commemorations held in December each year serve as a reminder of the human cost of industrial negligence and the ongoing need for vigilance. The date continues to resonate with communities affected by industrial accidents worldwide, symbolizing the ongoing struggle for justice, accountability, and safer industrial practices. December 1984 remains a potent symbol of the importance of prioritizing safety, transparency, and ethical conduct in industrial operations.

4. Bhopal, India

Bhopal, the capital city of Madhya Pradesh in central India, became tragically synonymous with industrial disaster following the events of December 1984. Prior to the tragedy, Bhopal was known for its lakes, historical sites, and burgeoning industrial sector. The gas leak at the Union Carbide India Limited pesticide plant irrevocably altered the city’s identity, leaving a lasting impact on its social fabric, environment, and public health. Understanding Bhopal’s geographical and socio-economic context is crucial for comprehending the scale and long-term consequences of the industrial disaster.

- Densely Populated Area

The pesticide plant’s location in a densely populated area exacerbated the disaster’s impact. The proximity of residential neighborhoods to the industrial facility meant that a large number of people were exposed to the toxic gas cloud. This highlighted the importance of urban planning and zoning regulations that consider the potential risks of industrial hazards and prioritize the safety of surrounding communities.

- Socio-Economic Vulnerability

Many residents living near the plant were from low-income communities with limited access to healthcare and resources. This socio-economic vulnerability magnified the disaster’s impact, hindering access to adequate medical treatment and long-term support for the affected population. The disaster underscored the disproportionate impact of industrial accidents on marginalized communities.

- Environmental Impact

The gas leak had a significant environmental impact on Bhopal and its surrounding areas. The contamination of soil, water, and air posed long-term health risks and ecological challenges. The disaster highlighted the importance of environmental regulations, monitoring, and remediation efforts in industrial areas.

- Long-Term Health Consequences

Bhopal continues to grapple with the long-term health consequences of the gas leak. Chronic respiratory illnesses, eye problems, neurological disorders, and birth defects continue to affect survivors and their descendants. The ongoing health crisis underscores the need for continued medical care, research, and support for the affected population.

The Bhopal gas tragedy remains a stark reminder of the devastating consequences of industrial accidents, particularly in densely populated areas with vulnerable populations. The disasters impact on Bhopal underscores the importance of stringent safety regulations, robust emergency preparedness, corporate accountability, and ongoing support for affected communities. Bhopals experience serves as a critical case study for understanding the complex interplay of industrial activity, urban planning, and public health, shaping ongoing discussions about industrial safety and environmental justice worldwide.

5. Industrial Negligence

Industrial negligence played a significant role in the Bhopal gas tragedy, transforming a preventable accident into a catastrophic disaster. Examining specific instances of negligence within the context of the Bhopal incident provides crucial insights into the factors that contributed to the tragedy’s scale and lasting impact. Understanding these factors is essential for preventing similar incidents in the future.

- Deferred Maintenance

Postponing essential maintenance to reduce costs created hazardous conditions at the Bhopal plant. Several safety systems, including the refrigeration unit for the MIC storage tank, the gas scrubber, and the flare tower, were non-functional or operating below capacity. This deferred maintenance directly contributed to the uncontrolled release of MIC gas. The Bhopal disaster serves as a stark example of the dangers of prioritizing cost-cutting over essential safety measures.

- Inadequate Safety Training

Insufficient training of plant personnel compromised their ability to respond effectively to the unfolding crisis. Workers lacked adequate knowledge of safety procedures and emergency protocols, contributing to the delayed and ineffective response to the gas leak. The Bhopal tragedy highlights the critical importance of comprehensive safety training programs for all personnel working with hazardous materials.

- Cost-Cutting Measures

Several cost-cutting measures implemented at the Bhopal plant compromised safety. Reducing the workforce, using less experienced personnel, and neglecting necessary safety upgrades contributed to a culture where safety was not prioritized. The disaster underscores the ethical responsibility of corporations to prioritize safety over profits and the potential consequences of neglecting essential safety investments.

- Lack of Regulatory Oversight

Insufficient regulatory oversight contributed to a lax safety environment at the Bhopal plant. Inspections were infrequent and enforcement of existing regulations was weak, allowing hazardous conditions to persist. The Bhopal tragedy highlighted the crucial role of robust regulatory frameworks and effective enforcement in ensuring industrial safety and preventing disasters.

The Bhopal gas tragedy serves as a paradigm of the devastating consequences of industrial negligence. The various forms of negligence, including deferred maintenance, inadequate training, cost-cutting measures, and insufficient regulatory oversight, combined to create a perfect storm for disaster. Understanding the specific instances of negligence in Bhopal provides critical lessons for industries worldwide, emphasizing the importance of prioritizing safety, investing in training, and adhering to stringent regulatory standards. The legacy of Bhopal underscores the enduring need for vigilance and a commitment to preventing future tragedies through responsible industrial practices.

Frequently Asked Questions about the Bhopal Gas Tragedy

This FAQ section addresses common questions about the Bhopal gas tragedy, providing concise and informative answers to promote a deeper understanding of this significant industrial disaster.

Question 1: What was the primary cause of the Bhopal gas leak?

Water entered a storage tank containing methyl isocyanate (MIC), triggering a runaway chemical reaction that resulted in a massive release of toxic gas.

Question 2: What were the immediate health effects of exposure to the gas?

Exposure to the MIC gas caused severe respiratory distress, burning eyes, skin irritation, vomiting, and in many cases, death.

Question 3: What are the long-term health consequences for survivors?

Survivors continue to experience chronic respiratory illnesses, eye problems, neurological disorders, and psychological trauma. Children born to survivors have also reported birth defects and developmental issues.

Question 4: Who was held responsible for the Bhopal gas tragedy?

Union Carbide India Limited (UCIL) was held responsible, though the extent of the parent company, Union Carbide Corporation’s (UCC), liability remained a point of legal contention. Legal proceedings and settlements spanned decades.

Question 5: What were the key lessons learned from the disaster?

The Bhopal tragedy highlighted the crucial importance of stringent safety regulations, robust emergency response plans, corporate accountability, and the ethical responsibility of companies handling hazardous materials. It also emphasized the need for greater transparency and community engagement in industrial processes.

Question 6: What is the current status of Bhopal?

Bhopal continues to recover from the disaster. Ongoing efforts focus on providing medical care and support to survivors, addressing environmental contamination, and commemorating the victims. The long-term health and social consequences of the tragedy continue to impact the city.

The Bhopal gas tragedy serves as a sobering reminder of the devastating consequences of industrial accidents. Understanding the causes, consequences, and lessons learned from this disaster is essential for preventing similar tragedies in the future.

Further exploration of this topic can involve researching the specific technical failures that led to the gas leak, the legal and political ramifications of the disaster, and the ongoing efforts to support the affected community. Continuing to learn from Bhopal remains crucial for promoting industrial safety and environmental justice worldwide.

The Continuing Legacy of the Bhopal Gas Tragedy

The Bhopal gas tragedy remains a significant event in industrial history, demonstrating the devastating consequences of industrial negligence and inadequate safety protocols. The release of methyl isocyanate (MIC) in December 1984 resulted in immediate fatalities and long-term health issues for thousands of people in Bhopal, India. The disaster exposed critical gaps in industrial safety standards, emergency preparedness, and corporate accountability, particularly concerning hazardous materials. The incident’s impact extended beyond immediate health crises, influencing legal frameworks, environmental regulations, and ethical considerations related to industrial practices globally. The role of Union Carbide India Limited (UCIL), the specific context of Bhopal, and the subsequent legal battles underscore the complex interplay of factors contributing to the tragedy’s scale and lasting legacy.

The Bhopal gas tragedy serves as a persistent reminder of the importance of prioritizing safety, promoting transparency, and ensuring corporate responsibility within industrial operations. Continued vigilance, rigorous regulatory oversight, and a commitment to ethical practices remain essential for preventing future industrial disasters. The lessons learned from Bhopal must continue to inform industrial safety standards and practices worldwide, promoting a future where industrial progress does not come at the expense of human lives and environmental well-being. The ongoing impact on Bhopal underscores the enduring need for comprehensive support for affected communities and the pursuit of environmental justice. Remembering and learning from Bhopal remains crucial for fostering a safer and more sustainable industrial landscape for all.